Pegasus Campus

Pegasus Institute for Excellence

Pegasus Institute for Excellence works with organisations, institutions, and teams to discover talent, buildability and realise their potential through soft skill development. The 8.72 acre campus since its inception 20 years ago had the principles of sustainability at its core. All previous structures on site were constructed using recycled materials like plastic and steel. However, due to a lack of maintenance and improper methods of construction, these buildings had deteriorated over time. The brief was to revitalise the campus using the expertise available at CGBMT using completely natural materials without interrupting the day-to-day functioning of the institute.

Design Philosophy

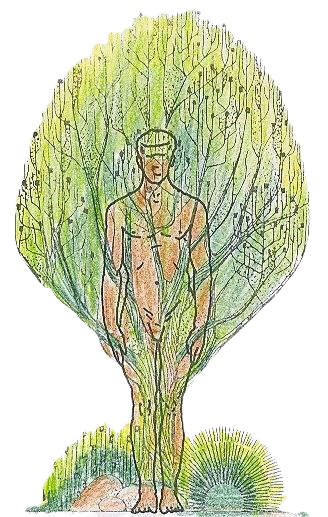

The concept was to connect all built spaces with nature. The materials which can make this possible would be natural materials like bamboo, local wood, mud and stone which would be locally available and low on embodied energy. Every space would be articulated by a large overhanging ceiling plane(the roof) with no vertical planes(walls) to maintain visual and spatial continuity with the lush greenery all around.

The overhangs shade the space under it while bamboo blinds running along the edge of the roof can be opened as and when necessary. The spaces are lit with natural light and clerestory in each hall that allows the hot air to escape out. In the first phase, the amphitheatre, rectangular hall, circular hall, and rainwater harvesting tank along the percolation well for water recharge were taken up. Sewage treatment also has been provided.

Amphitheatre

The idea was to work with the existing stage covering it with a new roof, while revamping the existing seating with new flooring and a taller roof.

The roof over the stage is a hyperbolic paraboloid curve and is oriented so that the existing trees are not disturbed. The main frame of the roof is made from bunching a number of bamboo splits together. 2” dia bamboos were bent and fixed over the frame to form the ribs along one direction. Further a grid of 1” bamboo splits was placed along both axes to achieve the profile of the curve. The bamboo roof is covered with tarpaulin fabric with a coating of brush bond on top for waterproofing.

The seating area had existing steel columns. The height of these columns was low and obstructed the view from the last row. Hence 3” dia bamboo was fixed to the existing steel column to get the desired height. The roof has two numbers of 2” dia bamboos as a beam along both directions resting on these columns. Further rafters in 2” dia bamboo are also placed to reduce the grid further down. Bamboo splits are used as infill between rafters and are covered with the same fabric with a brush bond on the top.

In the seating area, the height of the existing brick wall was altered and finished with yellow oxide flooring. A ramp along with a wider seating area for the wheelchair was added to make it universally accessible.

Hall complex

This location at the heart of the site had 2 existing halls, one circular and one rectangular. The proposed complex also consists of these halls respecting their location and is connected by a 90 feet long covered pathway.

Architectural features of the hall complex:

The existing rectangular hall had to be demolished and a new one built at the same location. The buildings are primarily made from bamboo and bricks. The structural system of the rectangular hall is bamboo truss made out of 3” dia bamboos placed around 9 feet apart. This truss is at two levels forming the clerestory for the hot air to escape out.

The roof consists of two layers of beaten bamboo with tar sheet in between for waterproofing. Beaten bamboo is an alternate to conventional roofing material which is more eco-friendly. In beaten bamboo, the round bamboo is flattened out and the node is cleaned.

The new circular hall was proposed to remove the central column in the earlier one with 40 feet diameter being increased along the perimeter as the circular hall turned into a spiral on the ground. The structural system is similar to the rectangular hall. The roof spirals around as it reaches the centre and forms 3 roofs at different levels with gap in-between them for hot air to escape out.