FlexiSanShell ©️

Determined to give back to society, FlexiSanShell was developed by CGBMT in collaboration with the local community. A rapidly deployable toilet with portability at its heart, the structure a lightweight & collapsible. It is ideal for use in disaster-stricken or remote locations, the structure can create a small shell for sanitation use. The structure serves as a blueprint for community-level initiatives for rapid fabrication. A small group of people can assemble up to 50 of these toilets per day.

It was shortlisted for the Red Dot Award for Product Design in 2017.

Background

CGBMT designed and built pre-fabricated toilets in response to the Nepal Earthquake and PM Modi's Swach Bharat Abhiyan to fulfill its social responsibility. While, as designers, it gave us an opportunity to give back to society, as students, it enabled us to put our theoretic learning to practical use.

After several months of testing and prototyping, CGBMT developed the FlexiSanShell. A prefabricated light toilet structure that can be easily dismantled, stored, and transported to various locations as required. The structure is light and collapsible for easy portability. It can be constructed by any member of the community and can be converted into a permanent one when required.

Unique features include:

Its ability to completely collapse on itself and be flat packed for ease of transportation. These 3’x 4’x 7’6’units can be manufactured and stored with authorities and are ready for emergency use during disasters.

On site they can be deployed with great speed unskilled labour can build up to 50 toilets each day. It can also be used for religious gatherings for seasonal tourist cottages, army camps, mountain expeditions slum sanitary programs, etc.

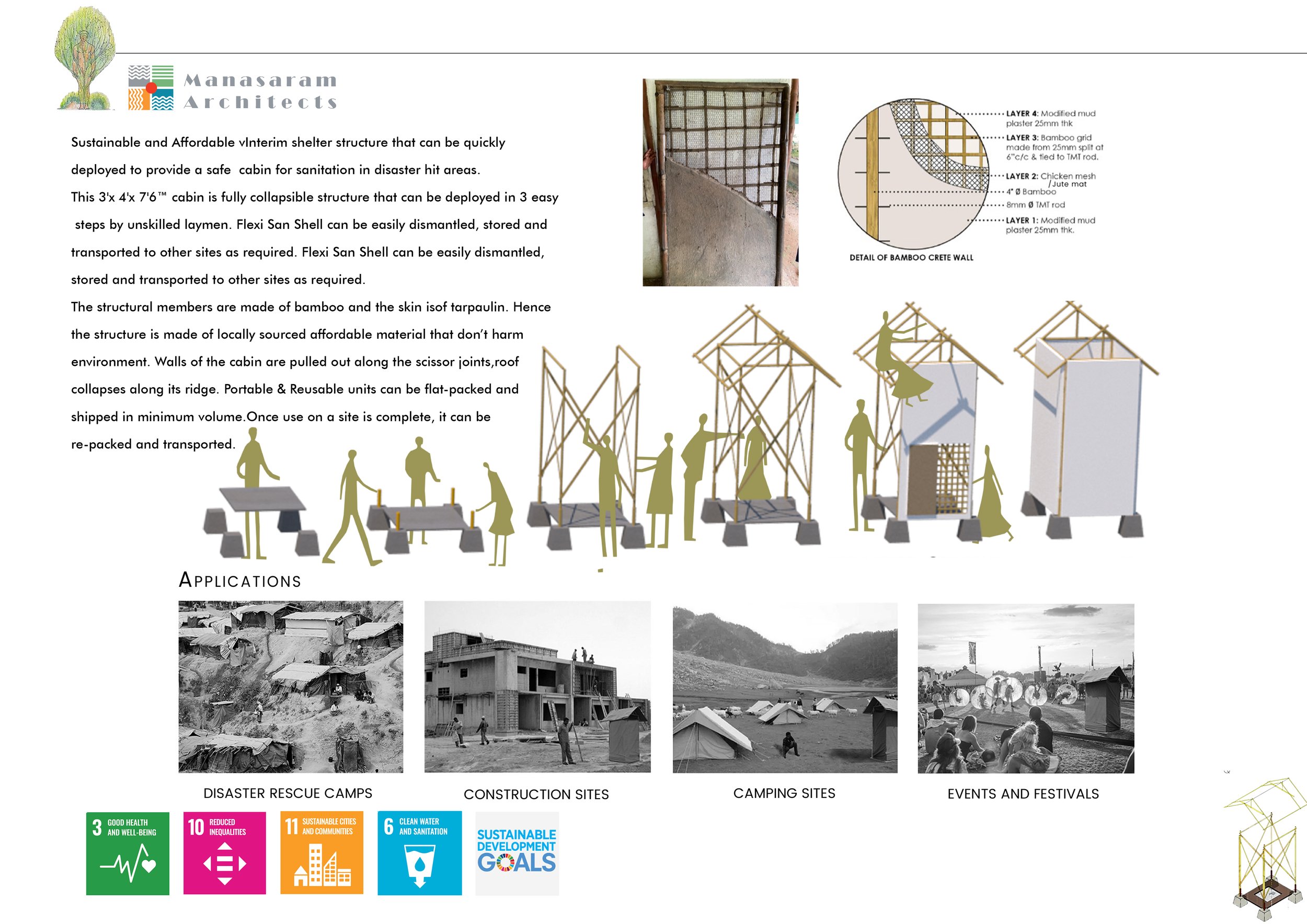

The structural members are made of bamboo and the skin is of tarpaulin. Hence, the structures are made of locally sourced affordable materials that do not harm the environment.

It can be converted into a permanent shelter from an interim one when required. Can be quickly deployed by anyone using three easy steps to provide a safe cabin for sanitation in disaster-hit areas.

The Elements

Wall Panels: Supported on 4 2” thick stocks of bamboo columns, three wall panels of the rectangular enclosure are cross-braced by 1.5” half bamboo splits. The split bracing is designed such that all four sides collapse on each other when folded, for transportation. This forms the structural skeleton of the toilet.

The Door: Designed along the same principle of collapsible cross-bracing, it spans the remaining shorter side of the enclosure.

Roof: Double-pitched roof collapsing along the central ridge. It is designed to rest on the columns and the tie beam. The tarpaulin will attach to the frame during the pre-fabrication process.

Covering: In order to keep the unit light and economical, water-proof tarpaulin was selected to form the skin of the structure. Refer to the sketch for joinery. Alternatively, an in-situ bamboo crete wall can also be built depending on site conditions.

Foundation (optional): For this prototype, 1’x1’x1’ (base dimensions) concrete pads were designed. The concrete ratio taken is 1.5:3:3. Enamel-painted 2.25” MS pipes with 3 pairs of pre-drilled holes were grouted to receive bamboo columns. An additional 2” deep 3”x3” notch was created to seat the floor slab. Alternatively, in-situ foundations in stone, etc. can be used depending on site conditions.

Floor Slab: A 2” deep 3’x4’ concrete slab precast with an Indian W.C. pan to be rested on the foundation notches.

Planning

The structure can be deployed as a single unit or clusters of different forms based on the context. A standalone unit can metamorphosise into a larger unit with various permutations and combinations.

The flexibility and versatility of the FlexiSanShell allows it to be deployed in –

Disaster prone areas

Temporary camps

Village Fairs

Ecologically sensitive areas

Large community gatherings

Temporary setup for events

Materials and Costing

Components (each toilet kit contains):

4 foundation pads with grouted pipes (optional)

1 floor slab with precast Indian WC pan

1 collapsed wall unit consisting of four columns, wall bracings, tie beams and door complete with attached tarpaulin

1 collapsed roof unit complete with attached tarpaulin

4 sets of bolts (for fixing columns to pipes), each having:

3 threaded rods

6 nuts

6 washers

Assembly

STEP 1

Insertion of foundations pads into ground and placing slab.

STEP 2

Opening wall unit with attached tarpaulin skin and inserting into foundation pads.

STEP 3

Opening the roof shell and lifting onto the main frame. Fixing the opened roof frame to the main structure.